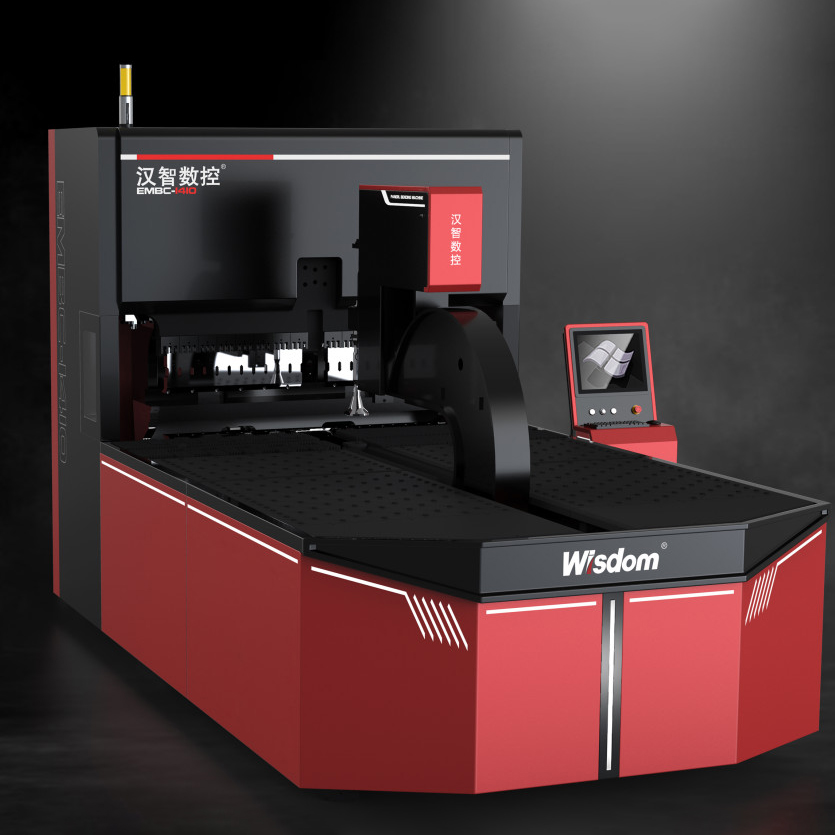

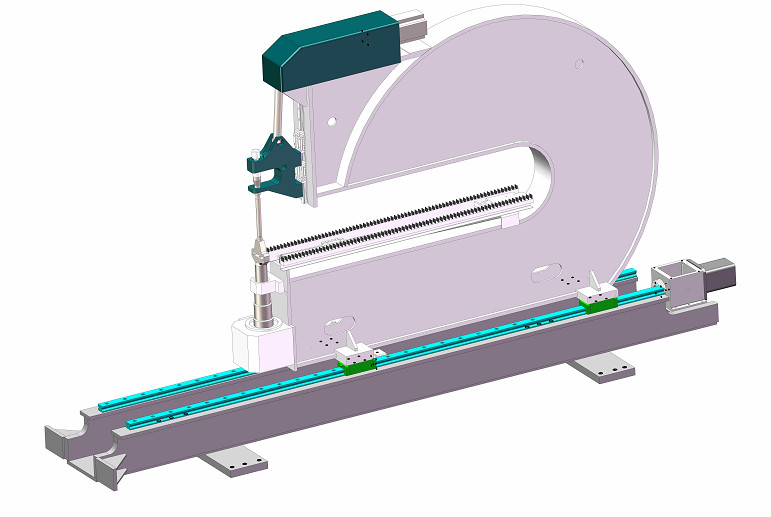

Iphaneli ye-Semi-automatic Bender EMBC 1402

imininingwane yemikhiqizo

| Cha. | Igama | Ipharamitha | Iyunithi |

| 1 | Ubude obukhulu | 1400 | mm |

| 2 | Ubukhulu.ububanzi | 1400 | mm |

| 3 | Okuncane.Ubude bokugoba | 200 | mm |

| 4 | Ububanzi obuncane bokugoba | 260 | mm |

| 5 | Ubukhulu be-Max.bending (MS, UTS410N/mm²) | 1 | mm |

| 6 | Min.bending ukujiya (MS,UTS410N/mm²) | 0.5 | mm |

| 7 | Ukuphakama okuphezulu | 170 | mm |

| 8 | Imodi yokulungisa ubude yokucindezela okuphezulu Imanuwali | ||

| 9 | Ukusetshenziswa kwamandla okumaphakathi | 2.2 | KW |

| 10 | Isisindo | 15 | T |

Izimpawu kanye nesakhiwo esiyinhloko

Mayelana nokwakhiwa komshini nokukhiqiza, i-Hebei Hanzhi CNC Machinery Co.,Ltd.igxile kakhulu kula maphuzu alandelayo:

1. Umqondo wokumaketha ophishekela ukusebenziseka futhi onge umsebenzisi yonke imali.

2. Umqondo wokuklama onokwethenjelwa kakhulu futhi onembe.

3. Izinto zokusetshenziswa ezisezingeni eliphezulu, izingxenye ezithengiwe nezindlela ezinhle zokucubungula.

4. Ukugcizelelwa okwengeziwe ekusebenziseni kalula nokugcinwa nokuphepha.

5. Izinga lokulungisa eliphansi kanye nezindleko zokunakekela embonini efanayo.

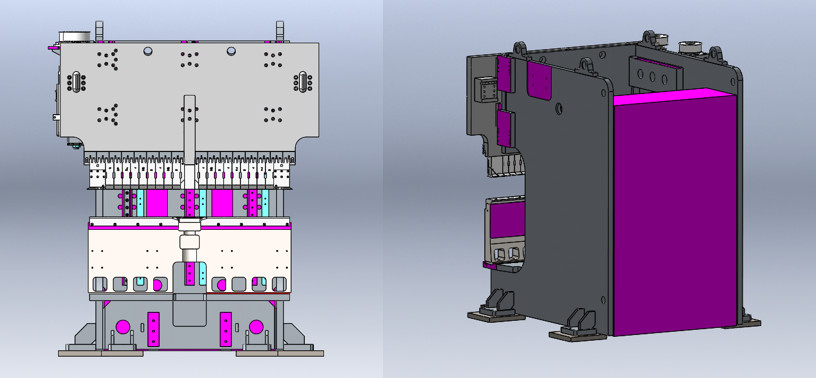

ifreyimu

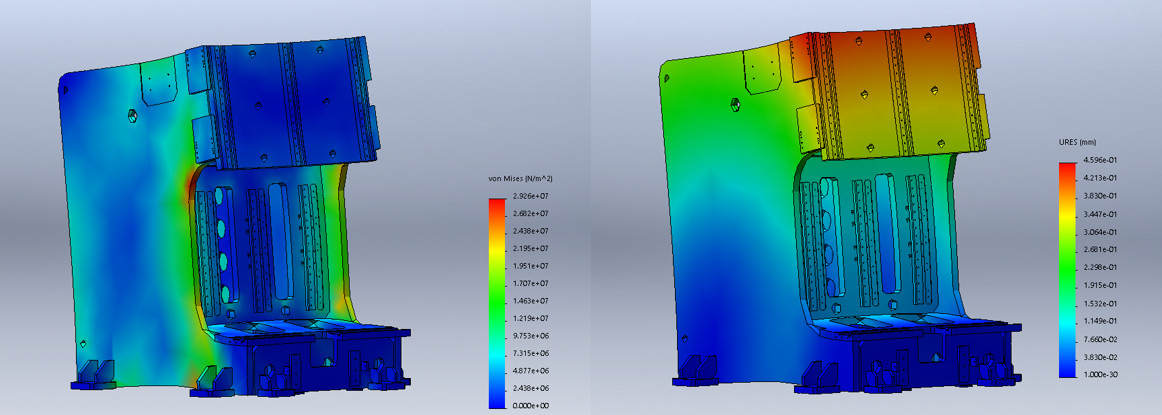

A. Ukwakha imodeli yesici esilinganiselwe se-3D: Ngokusekelwe kumodeli eqinile ye-3D ethuthukisiwe neyaklanywa, imodeli yesici esinamandla esinqunyiwe yakhelwe izibalo.Imodeli ibheka izingxenye eziyinhloko ekuxhumekeni kokudlulisa amandla.Amandla adluliselwa ku-bearing ngokusebenzisa uxhumano bese ukuhlaziywa kwamandla okuthwala kwenziwa.

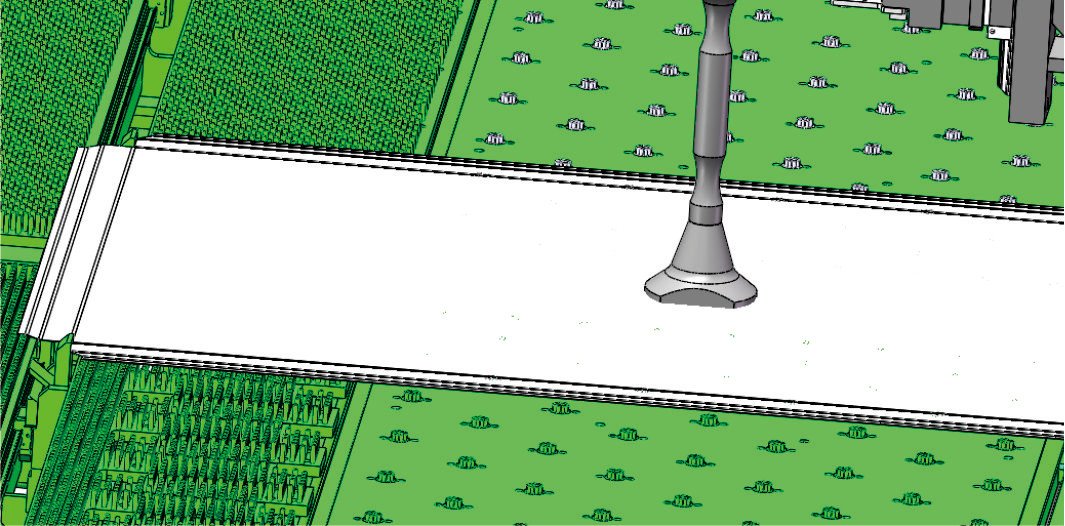

Fig. 1 Panel bender Finite element ashukumisayo yokumodela yomshini ophelele

B. Ukuhlaziywa Kwemiphumela Yokuhlaziya Okumile: Ngenxa yesivinini somshini esinensayo, ukuhlaziya amandla kungancishiswa kube inkinga emile.Ngokusekelwe kumthwalo wokucindezela ipuleti kanye nomthwalo ogobayo ohlangothini oluqondile lwekhanda lokusika, imiphumela yokucindezeleka ne-deformation iboniswa ngezansi.Ukucindezeleka okukhulu kubonakala emphinjeni womzimba ngokucindezeleka okukhulu kwe-21.2mpa kanye ne-deformation ephezulu ibonakala ekugcineni okuphezulu komzimba nge-deformation enkulu ye-0.30mm.

Ngokwemiphumela yokuhlaziywa kwesici esilinganiselwe sohlaka, insimbi ye-Q345 yakhethwa njengezinto ezibonakalayo;I-carbon dioxide shield welding yamukelwa;ukwelashwa kokushisa kwenziwa ukuze kuqedwe ukucindezeleka okubangelwa ukushisela;ngaleyo ndlela iqinisekisa ukunemba, ukuzinza kanye nokuqina okuphezulu kwemishini yokusebenza isikhathi eside.

Umdwebo 2 imiphumela yokuhlaziywa kokuguqulwa kokucindezeleka kohlaka

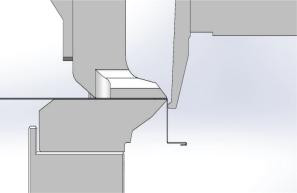

Inqama engaphezulu

Le ngxenye ikakhulukazi iqukethe isilayidi, isikulufu sokuhola se-torque ephezulu, isinciphisi, isitimela esiqondisayo, i-servo motor nokunye.Idrayivu eyinhloko ilawulwa yi-servo motor futhi imodi yokulawula i-servo synchronous control, engaqinisekisa ngokuphumelelayo ukunemba kokuma, isivinini esisheshayo nokulawulwa okuphezulu.Ukugcotshwa kwesikulufu sokuhola kanye nesitimela somhlahlandlela kusebenzisa ukuthambisa okuzenzakalelayo, futhi igrisi ingu-00#, okuqinisekisa impilo yesevisi nokunemba kwesikulufu sokuhola kanye nesitimela somhlahlandlela ukusebenza isikhathi eside.

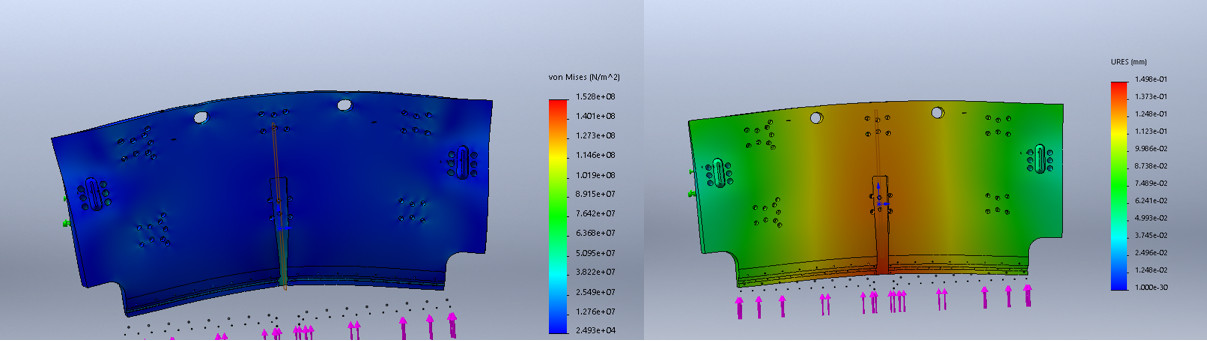

Imiphumela yokuhlaziywa kwe-Static yesilayidi esingaphezulu: umdwebo wezinso wokufuduka kwengcindezi wetafula eliphezulu ukhombisa ukuthi ukucindezeleka okukhulu kubonakala engxenyeni engenhla, ukucindezeleka okukhulu yi-152mpa, ukuguqulwa okuphezulu kubonakala ekugcineni kwetafula eliphezulu, ukuguquguquka okukhulu. ibe 0.15 mm

Umdwebo 3 imiphumela yokuhlaziywa kokususwa kwengcindezi yenqama

Ngokwemiphumela yokuhlaziywa kwesici esinqunyiwe senqama, insimbi ye-Q345 yakhethwa njengempahla;I-CO2 yokushisela ivikelwe yasetshenziswa;ukwelashwa kokushisa kwenziwa ukuze kuqedwe ukucindezeleka okubangelwa ukushisela;ngaleyo ndlela iqinisekisa ukunemba, ukuzinza kanye nokuqina okuphezulu kwemishini yokusebenza isikhathi eside.

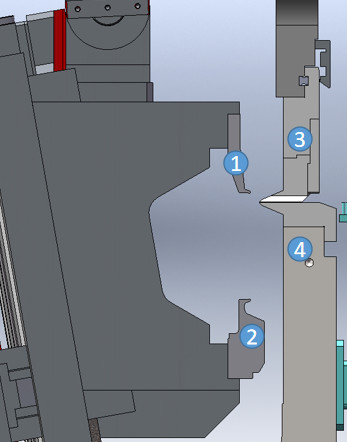

Iyunithi yokugoba

Ingxenye yokushayela kwamandla eyunithi yokugoba iqhutshwa yi-servo motor ngaphandle kokubandakanyeka kwesistimu ye-hydraulic, enezinzuzo ezinkulu mayelana nokunciphisa ukuguga nokudabuka kwezingxenye kanye nokusebenza kahle kokudlulisela, ngokuhambisana nenqubomgomo yokonga nokuvikelwa kwemvelo ekhuthazwayo. ngumbuso.

Ngokusho kokuhlelwa kolwazi lweshidi, isistimu ibala ngokuzenzakalelayo indawo yommese wokucindezela ophezulu 3 futhi ilawula ibanga phakathi kommese wokucindezela ophezulu 3 kanye nommese wokucindezela ophansi 4 ukulungisa ishidi;ngokusho kwesimiso sesistimu, kungakhathaliseki ukuthi lokhu kugoba kuphezulu noma phansi, ummese wokucindezela ophansi 2 noma ummese wokucindezela ophezulu 1 ulawulwa ukuze uhambe ngokushesha endaweni yokugoba;ngokuya ngama-engeli ahlukene wokusetha, ummese ogobayo ulawulwa ukuze uye endaweni ebaliwe ngefomula yokubala i-engeli enelungelo lobunikazi ukuze kuqedelwe ukugoba.

Ngokwezindlela ezihlukene zokugoba, zingahlukaniswa zibe ukugoba i-engeli, ukugoba kwe-arc enkulu, ukugoba okuyisicaba, njll., okuyikuphi ukugoba kwe-engeli kuhlukaniswe ukugobela phezulu nokugobela phansi.

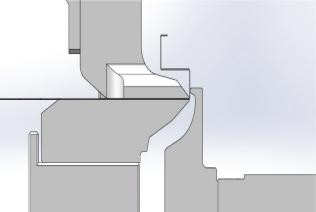

Iyunithi yokucindezela okuphezulu

Fig.6 Iyunithi yokucindezela okuphezulu

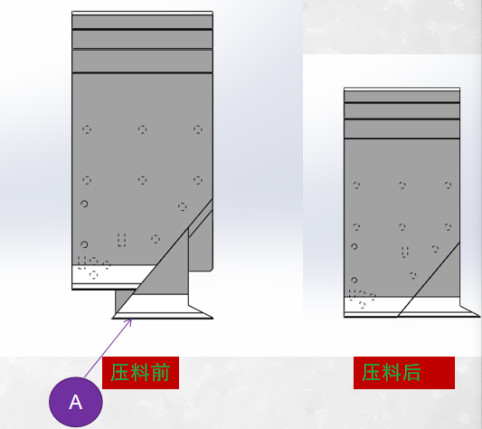

Iyunithi yokucindezela engenhla: ingxenye yazo zonke izinqubo zokugoba, isikhungo sokugoba se-EmbC esigcwele se-servo multilateral sifakwe iyunithi ekhethekile yokunyathelisa yangaphezulu engafakwa futhi ilungiswe ngesandla ubude bepuleti obuhlukene.

Ukuze kuhlangatshezwane nezidingo zebhokisi lokugoba lokugwema, sisungule indlela yokugwema okukhethekile.Ngaphambi kokucindezela, ingxenye yokufa kokugwema isesimweni ngaphambi kokucindezela kumdwebo bese ukuphakela kuqala.Ngemuva kokuncelisa, isesimweni ngemuva kokucindezela kumdwebo futhi ukugoba kuyaqala.Ngemva kokugoba, isilayidi esingaphezulu siyanyakaza.Ngesikhathi sokunyakaza kwesilayidi esingenhla, ingxenye A izohamba ngokuzenzakalelayo iye esimweni ngaphambi kokucindezela.Ngemuva kokuthi isilayidi esingaphezulu sithuthele endaweni emisiwe, ukunyakaza okulandelayo kuyaqala.

Fig.7 Ukugwema ibhokisi lokugoba

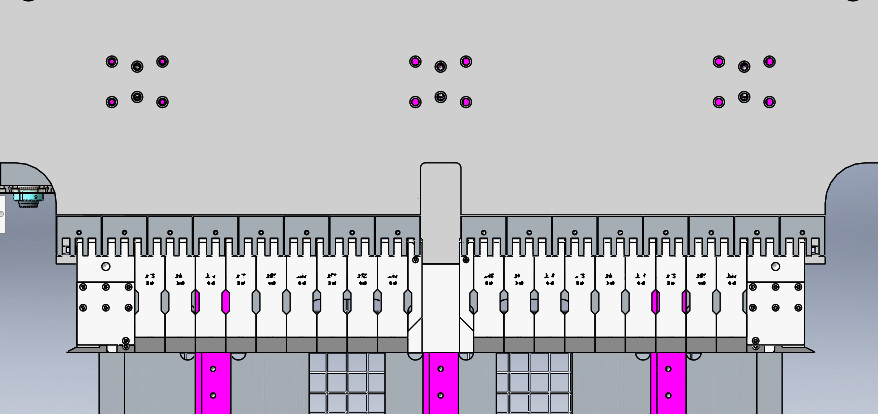

Ithuluzi

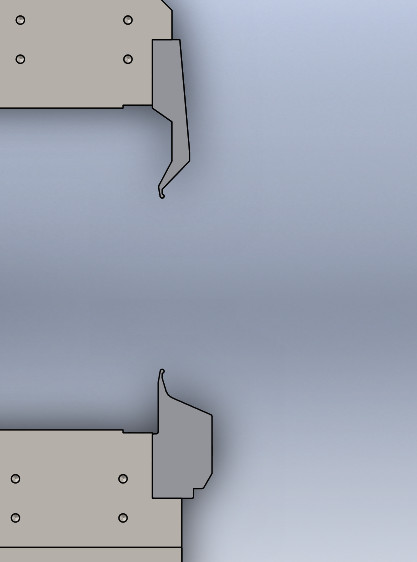

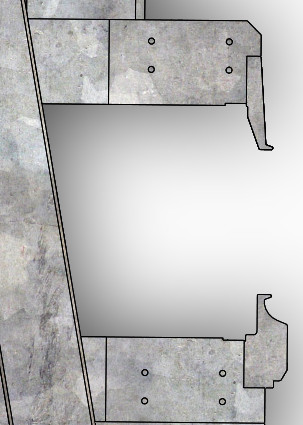

Amathuluzi okugoba ahlukaniswe ngamathuluzi okugoba aphezulu namathuluzi okugoba aphansi.Amathuluzi okugoba akhethekile angenziwa ngokwezifiso ngokuya ngezidingo ezahlukahlukene zekhasimende.

2. Iyunithi yokuphakela amapulangwe:

Ukunyakaza, ukugoqa kanye nokuzungezisa kweshidi lensimbi kulawulwa irobhothi 1, i-fixture 2 kanye nediski ejikelezayo engu-3 ngokulandelanayo.Phakathi nayo yonke inqubo yokwenza imishini, ukuphakelwa kweshidi lensimbi kulawulwa ama-servo motors, okuvumela ukuzenzekelayo kanye nokuma okusheshayo, ukunciphisa izikhathi zokunyakaza nokwandisa ukusebenza kahle.Ngenxa yezinqubo ezintsha zesakhiwo kanye nokusetshenziswa kokulawula okugcwele kwe-servo, ukugoqa nokujikeleza kwensimbi yeshidi kukwazi ukugcina ukunemba kuyo yonke inqubo yokusebenza yesikhungo sokugoba esihlangene.Kuma-workpiece amaningi ayinkimbinkimbi, ngisho nama-polygonal, ukunemba okuqhubekayo kokujikeleza okungu-0.001 kungaqinisekiswa.

3. Iyunithi yokubeka ipuleti:

Iyunithi yokumisa ipuleti iqukethe iphinikhodi yokubeka kwesokunxele, iphinikhodi yokubeka kwesokudla, iphinikhodi yokubeka ngaphambili kanye nephinikhodi yokumisa yangemuva;izikhonkwane zokumisa kwesokunxele nakwesokudla zibeka ipuleti kwesokunxele nakwesokudla.Iphinikhodi yokumisa ngaphambili kanye nephinikhodi yokumisa yangemuva ilawula indawo yangaphambili nangemuva yepuleti futhi iqinisekisa ukuthi ipuleti lihambisana nemimese yokucindezela engenhla nangaphansi, esetshenziselwa ukuqinisekisa ukunemba kokuma kwepuleti.

Iyunithi yokubeka ipuleti ingakwazi ukubeka ipuleti ngokuzenzakalelayo futhi igcwalise ngokuzenzakalelayo ukugoba kwamazwe amaningi ngesikhathi esisodwa, okufinyeza kakhulu isikhathi somjikelezo wokugoba, ilawula iphutha lokugunda ipuleti ekugobeni kokuqala futhi iqinisekise ukunemba kokugoba.

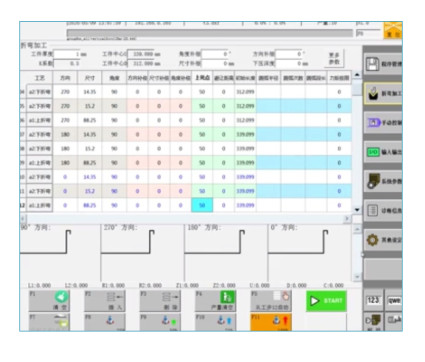

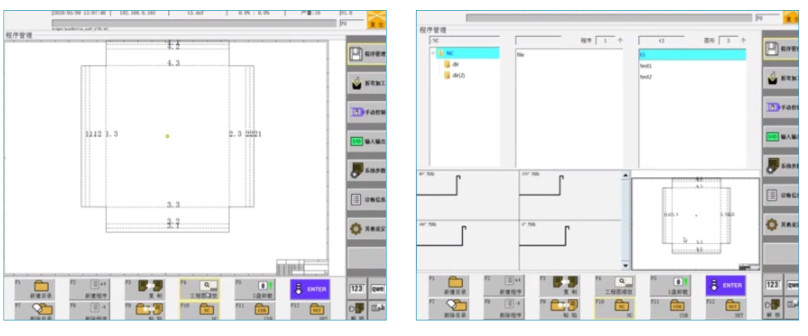

4.CNC uhlelo

A: Amasistimu nesofthiwe ye-CNC ethuthukisiwe ingasetshenziswa futhi ilawulwe ngokushesha futhi kalula

B: Izici ezibalulekile.

a) .Indlela yokulawula ibhasi ye-EtherCAT enokumelana nokuphazamiseka okuphezulu

b) Isekela uhlelo oluqondile, idatha yokugoqa yesinyathelo ngasinye ingafakwa efomini

c) Ukusekela ukugoba okugobile

d) Ukulawulwa kwe-servo kagesi ngokugcwele

e) Ukusekelwa kwesinxephezelo sokugoba

f) Ukusekelwa kohlelo olunezinhlangothi ezimbili

Umsebenzi wokuhlela we-2D, ngenisa idatha yomdwebo we-2D DXF, ukhiqize ngokuzenzakalelayo inqubo yokugoba, usayizi wokugoba, i-engeli yokugoba, i-rotation angle kanye nenye idatha.Ngemuva kokuqinisekisa, ukucutshungulwa kokugoba okuzenzakalelayo kungenziwa

Uhlu lwengxenye eyinhloko

| Cha. | Igama | Ibhrendi |

| 1 | Uhlaka | Ukuhlakanipha |

| 2 | Ithuluzi | Ukuhlakanipha |

| 3 | Iyunithi yokugoba | Ukuhlakanipha |

| 4 | Isistimu ye-CNC | Ukuhlakanipha |

| 5 | I-Servo motor | Ukuhlakanipha |

| 6 | Umshayeli we-Servo | Ukuhlakanipha |

| 7 | Ujantshi | Ukuhlakanipha |

| 8 | I-Ballscrew | Ukuhlakanipha |

| 9 | Umnciphisi | I-Taiwan |

| 10 | Umaphuli | Schneider |

| 11 | Inkinobho | Schneider |

| 12 | Ingxenye kagesi | Schneider |

| 13 | Ikhebula | Yicu |

| 14 | I-Proximity switch | u-Omron |

| 15 | Ukuzala | I-SKF/NSK/NAICH |

4) Ukwakhiwa, ukwakhiwa, ukuhlolwa nokufakwa kwethuluzi lomshini kuhlangabezana namazinga alandelayo.

1, GB17120-1997

2, Q/321088JWB19-2012

3, GB14349-2011

Ingxenye esele kanye nohlu lwamathuluzi

| Cha. | Igama | Qt. | Phawula |

| 1 | Ibhokisi lamathuluzi | 1 | |

| 2 | Faka iphedi | 8 | |

| 3 | Iisipanela se-hexagon | 1 isethi | |

| 4 | Isibhamu sokugcwalisa amafutha mathupha | 1 | |

| 5 | Imanuwali yesistimu ye-CNC | 1 | |

| 6 | isipanela esivulekile | 1 |