Umshini Wokushisela we-Metal Laser Welding Ongcono Kakhulu

Imishini yokushisela i-laser iye yashintsha indlela izingxenye zensimbi ezixhunywe ngayo ezimbonini ezihlukahlukene.Ikhono labo lokuhlanganisa izinsimbi ngaphandle komthungo besebenzisa imishayo ye-laser egxilile ibenza babaluleke kakhulu ezimbonini ezifana nezezimoto, i-aerospace kanye nezokwelapha.Phakathi kwezinhlobo ezahlukene zemishini yokushisela i-laser etholakala emakethe,imishini yokushisela i-laser yensimbi ephathwayozibhekwa njengenye yezinketho ezinhle kakhulu zokuguquguquka, ukusebenza kahle, kanye nokusetshenziswa kalula.

I-laser welder yensimbi ephathwayo iyithuluzi elihlangene, eliphathwayo elenza opharetha bakwazi ukushisela izingxenye zensimbi ngokunemba.Inikeza ukuguquguquka kokusebenza ezindaweni ezihlukahlukene nama-engeli, ukuqinisekisa ukuthi ama-welders angafinyelela ezindaweni eziqinile kanye namajoyini ayinkimbinkimbi.Lokhu kuguquguquka okukhethekile kuyenza ilungele izimboni ezidinga izinqubo zokushisela eziyinkimbinkimbi.

Esinye sezici ezivelele zamashiseli ensimbi aphathwa ngesandla ukuthi kulula ukusetha nokusebenza kwawo.Iqeda isidingo semishini emikhulu, inciphisa isikhathi sokusetha nomzamo odingekayo.Ama-welders manje angakwazi ukwenza imisebenzi yokushisela kahle futhi kalula.Lokhu lula kunenzuzo ezimbonini ezidinga izikhathi zokushintsha ngokushesha kanye nokukhiqizwa kwevolumu ephezulu.

Ukunemba nokunemba kwamashisela ensimbi aphathwa ngesandla akufaniswe.I-laser beam egxilile iqinisekisa ukuthi indawo eqondiwe ithola ukushisa ngokulinganayo, ivimbela noma yikuphi ukuguqulwa noma ukulimala kwezinto ezizungezile.Umphumela uba ijoyinti elishiselwe elihlanzekile, eliqinile neliqinile.Leli zinga lokunemba libaluleke kakhulu ezimbonini ezifana ne-aerospace nezokwelapha, lapho ikhwalithi nokuthembeka kwamalunga ashiselwe kubaluleke kakhulu.

Ngokungeziwe emandleni okushisela aphakeme, abashiseli bensimbi abaphathwa ngesandla banikeza uhla lwezinye izinzuzo.Inqubo yayo ye-welding engathinteki inciphisa ingozi yokungcola kanye nokulimala endaweni yokusebenza.Iphinde iqede isidingo sezinto ezengeziwe ezifana nensimbi yokugcwalisa, i-flux noma igesi yokuvikela, ukunciphisa izindleko nokwandisa umkhiqizo.

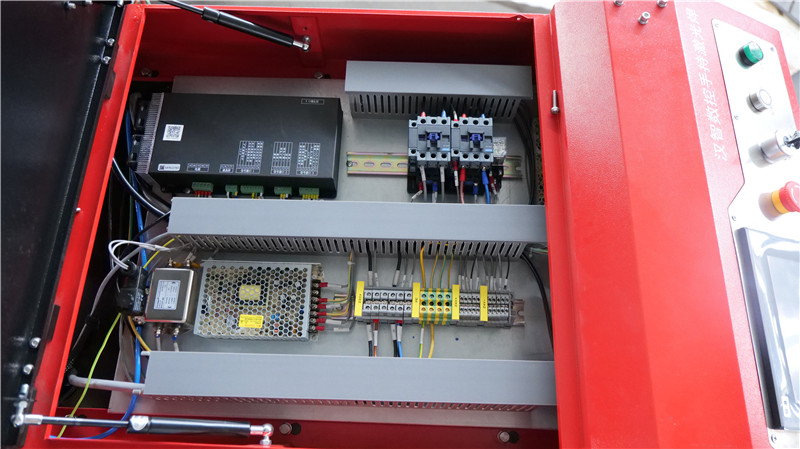

Lapho ucabanga ukuthenga umshini wokushisela, kubalulekile ukukhetha ohlangabezana nezidingo zakho ezithile.I-laser yensimbi engcono kakhulu ephathwayoumshini wokushisela uyathengiswakufanele ibe nokukhipha amandla okufanelekile, ubude be-pulse, kanye ne-laser wavelength kuhlelo lwakho lokusebenza oluhlosiwe.Kufanele futhi ifakwe izici ezisebenziseka kalula ezenza kube lula ku-opharetha ukuzulazula nokulawula umshini.

Ukwengeza, lapho uthenga umshini wokushisela i-laser wensimbi ophathwa ngesandla, kubalulekile ukukhetha umkhiqizi noma umphakeli ohloniphekile nothembekile.Bheka inkampani enerekhodi eliqinisekisiwe lokuletha imikhiqizo yekhwalithi ephezulu kanye nenkonzo yamakhasimende enhle kakhulu.Kufanele banikeze ukwesekwa okubanzi kobuchwepheshe, ukuqeqeshwa, kanye newaranti ukuze baqinisekise ukuthi umshini usebenza kahle futhi uhlangabezana nokulindelweyo.

Sekukonke, i-laser welder yensimbi ephathwayo iyithuluzi eliguquguqukayo nelisebenzayo lokuhlanganisa izingcezu zensimbi ndawonye.Usayizi wayo ohlangene, ukusetshenziswa kalula nokunemba okukhethekile kuyenza ibe yisinqumo esihle kakhulu ezimbonini ezahlukahlukene.Lapho ufuna ibest welding umshiniuma uthengiswa, kubalulekile ukuthi ucabangele izidingo zakho ezithile bese ukhetha umkhiqizi noma umphakeli ohloniphekile.Ngomshini wokushisela we-laser wensimbi ophathwayo ophathwayo, ungafinyelela amalunga aphezulu we-weld futhi wandise ukukhiqiza kwenqubo yakho yokushisela.

Ividiyo

Isicelo

I-laser welding wuhlobo lokushisela olusebenzisa i-laser ukuncibilikisa izinto ezihlanganiswayo.Isebenza ezimbonini eziningi, njengezezimoto, i-aerospace, kanye nokukhiqizwa kwemishini yezokwelapha.I-laser welding ingasetshenziselwa ukuhlanganisa izinto okunzima ukushisela, okuhlanganisa i-aluminium nama-alloys ensimbi engagqwali.Iphinde idale ama-welds anembe kakhudlwana kunezindlela zokushisela zendabuko ngenxa yokunemba nokunemba kwayo.

umshini wokushisela we-laser Izixwayiso zokusetshenziswa

1. Gqoka izingubo zokuzivikela, amagilavu nezibuko lapho usebenzisa umshini wokushisela we-laser.2. Sicela uqinisekise ukuthi zonke izingxenye zomshini zigcinwe kahle futhi zisesimweni esihle ngaphambi kokusetshenziswa.3. Qinisekisa ukuthi indawo yokusebenza ingena kahle umoya ukuvimbela ukuqoqwa kwezinto eziyingozi ngenxa yemisebenzi yokushisela.4. Ngesikhathi sokusebenza komshini wokushisela i-laser, sicela unake izingozi ezingaba khona njengomlilo, intuthu noma izinhlansi.5. Bheka ukuxhuma okuxekethile noma izintambo ezingasebenzi kahle ngaphambi kokusetshenziswa, futhi uthathe izinyathelo ezifanele uma kudingekile ukuze ugweme noma iyiphi ingozi yokushaqeka kagesi ehlobene nokuphakelwa kwamandla kagesi omshini noma izingxenye zawo zangaphakathi/amasekhethi.6. Lapho wenza imisebenzi yokushisela nge-laser ezinsimbi ezifana nensimbi ne-aluminium, ibanga eliphephile kufanele ligcinwe ezintweni ezivuthayo ezifana nephepha nepulasitiki, ezivutha ngaphansi kwezimo ezithile.7. Ungashisi kakhulu impahla ngokusebenzisa ama-pulses amade kakhulu, lokhu kungakhubaza ingxenye eshiselwe noma kubangele ukulimala okushisayo endaweni ezungezile.8. Qaphela ukulahla izingcezu ezishisayo eziphuma ngemva kwenqubo yokuhlanganisa.

imininingwane show